SOLIDWORKS 2025 optimises your product development process, enabling you to get more done in less time, with the ability to freely iterate and enhance designs, while creating high-performing, high-quality designs refined to the highest possible degree.

Invenio is an authorised SOLIDWORKS reseller in Australia and New Zealand.

What’s New in SOLIDWORKS 2025

Make informed decisions. Accelerate product development. Connect people and data. Explore the user-driven enhancements ready to help you and your teams work smarter, faster, and together.

Get an overview of the powerful new features created to help you improve productivity by working smarter, faster, and together with industry-leading product development tools.

Enhance your 3D CAD capabilities by connecting your design processes to the 3DEXPERIENCE® platform for access to powerful tools across the entire product development lifecycle, including data management, collaboration, advanced simulation, manufacturing, and production.

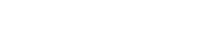

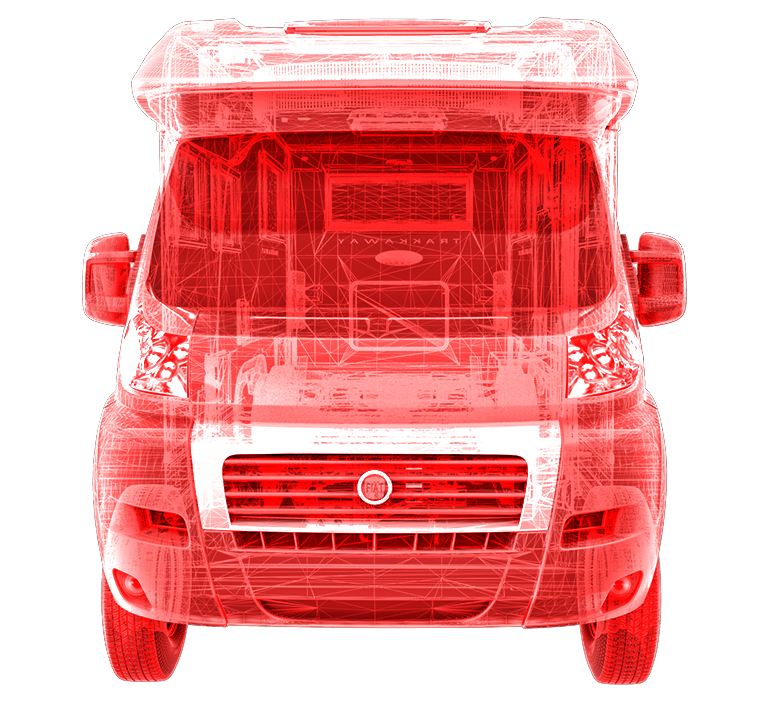

SOLIDWORKS 3D CAD

Intuitive 3D design and product development solutions from SOLIDWORKS let you conceptualise, create, validate, communicate, manage, and transform your innovative ideas into great product designs.

Dramatically improve the way you develop and manufacture products. As the foundation for the entire SOLIDWORKS suite of product development solutions, SOLIDWORKS CAD packages cover design, simulation, cost estimation, manufacturability checks, CAM, sustainable design, and data management.

By providing best-in-class, tightly integrated tools for every area of product development and management, SOLIDWORKS enables enterprises to speed each stage of the development cycle by allowing all disciplines to work concurrently, starting with concepts all the way through to manufacturing.

Benefits

- Powerful design functionality and ease of use

- Process-driven solutions keep focus on big picture

- Easy-to-deploy data management facilitates collaboration

- Virtual prototyping drives innovation, improves quality

- Integrated design-to-manufacturing gets products built faster

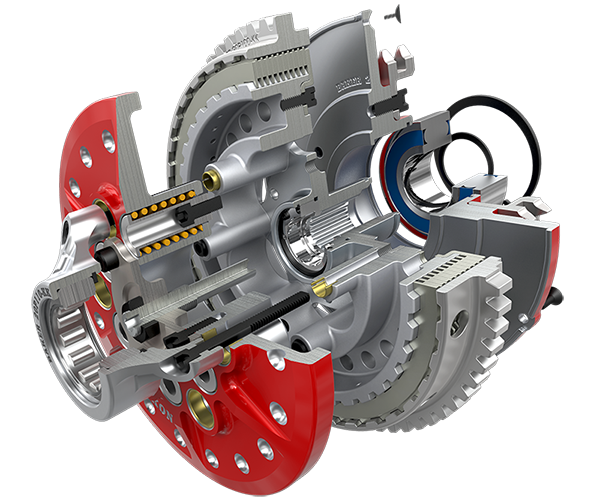

Simulation Solutions

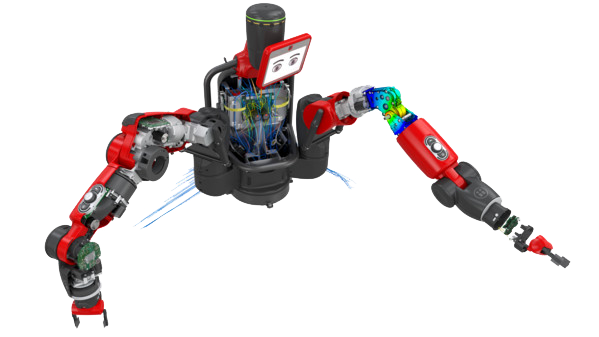

SOLIDWORKS Simulation is a comprehensive structural analysis solution fully embedded within SOLIDWORKS that can be used by designers and analysts alike to enable companies to get their products to market faster and with less cost without sacrificing quality or performance.

SOLIDWORKS Simulation is a portfolio of structural analysis solutions using the Finite Element Analysis (FEA) method to predict a product’s real world physical behaviour by virtually testing CAD models. The portfolio delivers linear, non-linear static and dynamic analysis solutions divided into three products: Simulation Standard, Simulation Professional, and Simulation Premium, each of which adds easy-to-use capabilities to solve ever more challenging problems.

Benefits

- Evaluates the performance of multiple variables at a rapid pace.

- Reduces time-to-market by quickly determining optimal design solutions.

- Predicts product performance, Factor of Safety (FOS), and fatigue capabilities early-on in the process.

- Reduces materials cost. SOLIDWORKS Simulation enables design teams to safely remove unnecessary material.

- By virtually testing and refining your designs first, the costly testing and certification process is streamlined reducing your time-to-market.

Flow Simulation

SOLIDWORKS Flow Simulation is a general-purpose fluid flow and heat transfer simulation tool integrated with SOLIDWORKS 3D CAD. Capable of simulating both low-speed and supersonic flows, this powerful 3D design simulation tool enables true concurrent engineering and brings the critical impact of fluid flow analysis and heat transfer into the hands of every designer. In addition to SOLIDWORKS Flow Simulation, designers can simulate the effects of fans and rotating components on the fluid flow and well as component heating and cooling.

Benefits

- Evaluates product performance while changing multiple variables at a rapid pace.

- Reduces time-to-market by quickly determining optimal design solutions and reducing physical prototypes.

- Enables better cost control through reduced rework and higher quality.

- Delivers more accurate proposals.

SOLIDWORKS Plastics

Predict and avoid manufacturing defects in plastic part and injection mould designs, eliminating costly rework, improving part quality, and decreasing time to market.

SOLIDWORKS Plastics offers Computer-Aided Engineering (CAE) simulation tools that predict how melted plastic flows during the injection moulding process—the manufacturing method used to produce more than 80% of all plastics products. The ability to predict how the plastic will flow allows the prediction of manufacturing-related defects. By being able to predict these defects, users can change mould geometry, processing conditions, or the plastic material used to minimise potential defects, thus saving energy, natural resources, time, and money.

Benefits

- Avoid Hidden Costs: SOLIDWORKS Plastics products can be used to optimise part wall thickness, gate locations, runner system size, and layout to ensure the mould works right the first time, reducing or eliminating the need for rework.

- Reduce Manufacturing Defects and Scrap: SOLIDWORKS Plastics makes it easy to analyse design iterations at the earliest stages of product development—when the cost of change is least and the impact on manufacturability is greatest. This improves part quality and minimises scrap rates.

- Reduce Time-to-Market Delays: SOLIDWORKS Plastics helps to predict and avoid potential manufacturing defects before any mould tooling is cut, virtually eliminating the need for time-consuming and costly mold rework and ensuring project deadlines and ship dates are met on-time and within budget.

- Avoid Inefficient “Islands of Automation”: SOLIDWORKS Plastics provides automated report generation tools that facilitate the sharing and interpretation of simulation results, allowing increased collaboration among development teams at different sites.

PRODUCT DATA MANAGEMENT (PDM)

SOLIDWORKS PDM is a mainstream data management system that stores and organises engineering CAD data and other documents in a central vault that has a relational database to manage all the information about the files and references, users and group permissions, electronic workflow processes and more. SOLIDWORKS PDM is built into Windows Explorer so users work in a familiar environment but with much more information and control.

SOLIDWORKS PDM uses an organised local cache where files are automatically retrieved from the central file server (Archive Server) and placed in the user’s local cache on their hard drive. This vastly increases performance over opening and saving files on network shared folders. If a file needs to be edited, the user will check out the file which gives them rights access to it. After editing is complete, the file is copied back to the Archive Server via the check-in process. The check-in process automatically creates a new version of the file.

Benefits

- Saves time searching with a secure centralised location for all design documents and utilisation of configurable search cards which make it easy to enter search criteria

- Controls access to data so the right users have access at the right time based on where a file is in the approval process

- Effective version control helps avoid rework and scrap caused by working from the outdated versions of 3D models and drawings

- Enables remote design locations to receive real-time updates on design changes coupled with automatic notifications

- Avoids having to spend time looking for or recreating documents that have been, moved, renamed, misplaced, or mistakenly deleted by unauthorised users

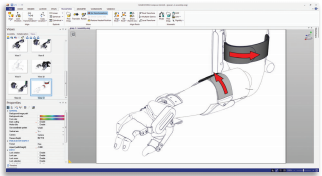

SOLIDWORKS Composer

SOLIDWORKS Composer gives you the tools to design and produce technical communication deliverables in parallel with product development—so your documentation keeps up with your design changes and is ready with your product. The intuitive SOLIDWORKS Composer interface enables you to create highly detailed 2D and 3D graphics with precise control to highlight areas of interest and focus on specific components. You can easily output 3D interactive animations to create a realistic 3D environment for interactive training or compelling marketing presentations.